+44 1332 751755

+44 1332 751755

+44 774 765 3822

+44 774 765 3822

[javascript protected email address]

[javascript protected email address]

Services

WJ Metal Products Ltd are able to supply most materials from 100g to several tonnes.

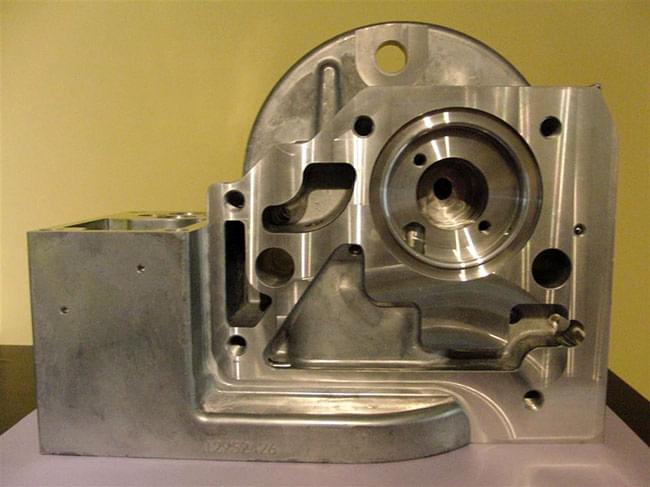

Components are manufactured using various production processes including:

- Sand Casting:- vertical and horizontal moulding, green chemically bonded, shell, hot box sand.

- Investment:- lost wax, true investment.

- Lost Foam

- Die Cast:- gravity, low and high pressure.

- Forging:- 2000 tonne hydraulic presses.

- Pressing

- CNC Machining:- horizontal and vertical.

- Complex Fabrication:- Assemblies produced using dissimilar materials (eg steel, stainless steel and plastic injection mouldings)

Quality and Inspection

The highest quality can be achieved from our suppliers that have simulation systems, including Magma and Procast, 3D measuring equipment and Radiographic machines.

We have access to the latest simulation systems to verify tooling design, methoding and gating and feeding system design. This simulates the casting and cooling process enabling corrections to metal flows and feeding before first off parts are produced.

If you have a clear product specification or simply an idea you need to turn into reality, we can visit you anywhere in the world to discuss your requirements, advise regarding materials and discuss any design improvements. Subsequent to the discussions, we can produce 3D models and/or print and appoint a suitable supplier. Throughout the production process, we will liaise with the supplier to discuss tooling, material specification and any special requirements as well as carrying out inspections.

Even complex fabrications can be converted to castings for volume production with significant cost advantages.

We will keep you informed each step of the way and ensure that all your requirements are met. We can even arrange the delivery, whether you require simple F.O.B. or products delivered door to door, you just tell us where you want it and we will deal with all the logistics and legalities.